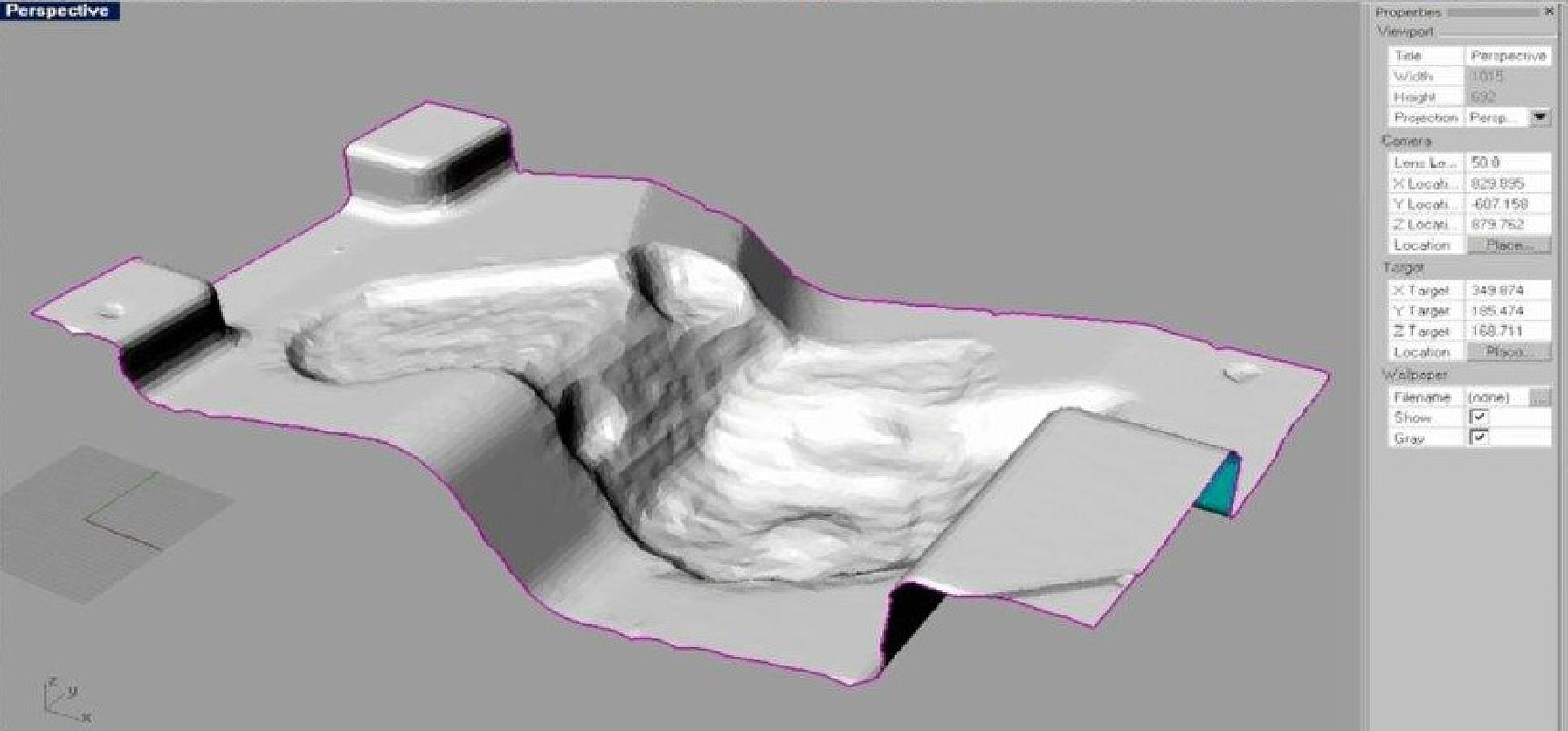

Section snippets Kinematic relation analysisĭuring the roll-forging process, there exists a conjugate relationship in geometry and kinematics between the surface of rolling die and that of forging piece, that is, forging contour is the enveloping surface of rolling die and vice versa, rolling die contour is the enveloping surface of forging piece, as shown in Fig. In this paper, an approach for the design of rolling-dies will be proposed based on the analysis of the conjugate relationship between the surface of rolling-die and that of forging piece, then the roll-forging techniques for a representative front axle of automobile will be presented together with the details of rolling die design.

The forming process of roll-forging is very different from that of die-forging, the same is true for the design of rolling dies. The roll-forging technique makes it possible to manufacture large forging parts at lower-cost. The capacity of the equipment used in roll-forging is much smaller than that used in die-forging and because the roll-forging is a steady deformation process, the high and big workshops and huge foundations are unnecessary, consequently, the investment in equipment and civil construction is saved significantly. The development of roll-forging technique will open a new way to form large forging parts. And the roll-forging techniques for many important parts such as front axles of automobiles, connecting rod of the diesel engine, taper leaf springs for vehicles, turbine blades, and ploughshares, etc. In recent years, roll-forging technology has been used extensively in China in the productions of the parts of automobiles, trucks, tractors and aircrafts. In addition, due to the rational stream-line-distribution of metal fibres and uniformly distributed metallographic structure, roll-forging products exhibit better mechanical properties and reliability than those manufactured by die-forging or machining. It has remarkable advantages such as high productivity, high utilization rate of material, good labour condition, simple equipment structure, long life of the rolling dies and so on. Roll-forging can be used in both the preforming procedure and the finish forming procedure of forging process. In this process, the desired shape of metal part is produced by rolling the hot billet between two rotating dies having appropriately profiled grooves. Roll-forging is a process to manufacture axle-like and plate-like metal parts.

0 kommentar(er)

0 kommentar(er)